Typical pressure relief applications include HRSG units steam boiler. PULSCO Vent Silencers reduce the noise generated by the expansion of gas or steam from elevated pressures to atmospheric pressure.

Dürr Universals vent silencers are used around the world in many applications.

. The acoustic fill is long fiber noncombustible inert vermin and moisture-resistant fiberglass of at least four-pound-per-cubic-foot density protected. Our Vent Silencers are completely customizable and. Equations displayed for easy reference.

Imperial 1030 Silencer Diameter CA Material Carbon steel Inlet pipe diameter In 10xinches - CR 080 outer Ø VS Residential VS Critical VS Super critical VS Extreme VS Residential VS Critical VS Super critical VS Extreme 13 20 20 20 24 84 86 95 108. Applicable regulations and design codes differ from one another. Vent silencer Acoustic performance I Measurement unit.

If you have the requirements Axces Steam and Flow Control can help you with your custom made Vent Silencer. Our competitive pricing timely service performance assurance and premium customer service for the highest quality products in the industry. Applications that require silencers.

Up next is design temperature. After a suitably sized device has been selected it is installed at the pipeline purge outlets where fluid expansion takes place. Problem is I need to deal quickly angry local residents with two steam relief vents which currently discharge to a common 8 uncoupled vent pipe.

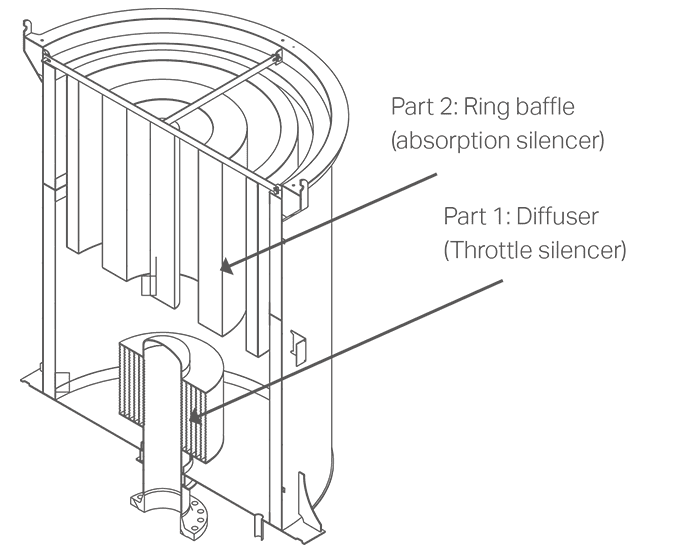

A vent silencer diffuses the turbulent flow in. Pressurized steam or gas leaving a pipe can result in turbulent flow at high velocities. Vents steam vents safety relief valve outlets system blow downs and purge outlets etc.

Includes 53 different calculations. As such it must be carried out by experiencedcompetent professionals. All our components are calculated and subjected to internal pressure.

To reduce work place noise levels to a desired occupational limit. This noise is produced by rapid turbulence of the vented gas jet and the release of energy from the compressed gas. Selection of the appropriate silencer sizing relative to the steam flow.

This includes a steam vent. Firstly there is design pressure. Our staff has countless years of steam vent silencers experience in the design manufacturing and application of integrating silencers with waste heat recovery components and silencers with catalytic converters for emission control.

An analysis is developed to aid in the design of the acoustically. With the right system they can control the. Online calculator to quickly determine Pipe Sizing for Steam Vent.

An example is used to illustrate an approach to the design of an acoustically treated expansion chamber for a typical noise problem caused by superheated steam vented to the atmosphere. A fact you may not know about silencers is that they all have some interesting mechanical characteristics. The issue here is designing.

Each of our steam silencer designs aims to attenuate the noise generated by the expansion of gas or steam from elevated pressures to atmospheric pressure. Vent silencer design is an experts job. A vent silencer is a device intended to reduce the very high noise levels created when high pressure gas or steam is expanded to the atmosphere.

Vent and blow down noise is a function of upstream pressure and temperature type of gas being vented the valve size and type plus the effect of down stream piping. In industrial settings experts can use steam for a number of things including heating and sterilisation. How they work The IMS-designed VT series.

Due to the many variables and the complexity of vent silencer sizing selection and design computer optimization methods are employed. Most of the noise occurs at the expansion. One is set 22 bar 7050kgh other 12 bar 23350kgh.

Steam venting in power generation applications Natural gas compressor station and pipeline blowdowns Process control and relief valves in industrial applications Blowdown tanks and autoclaves Bypass valves on blowers and compressors Steam ejectors and hogging vents Discharge of high-pressure gas to substantially lower. Construction and compliance are according to the applicable Pressure Vessel Code for the district or industry of your operations. The word silencer is instead referred to as blowdown when they are blowing.

Vent Silencer - Steam 15 Outer dimension 3 Product group VS Family. The terms vent silencer and blowdown silencer refer to the relative application for which each one is used. DB Noise Reduction steam silencers control sound through a reactive-absorptive process which provides good attenuation across all octave frequency bands.

Noise control problems exist where high pressure high temperature gasses are vented to the atmosphere. The team will design something that fits in with the systems to reduce the sound and the harm it can cause. Annular vent silencers are assembled with structural members that accommodate thermal expansion in high-temperature applications.

Stopson Italianas Steam Vent Silencers. The predominant use of the IMS range of Vent Silencer is within typical applications such as steam ejectors steam and gas vents process vents turbine or compressor. The specification of the proper steam silencer for a given application is based a number of factors.

The size is generally dictated by velocity required noise reduction and allowable pressure drop. When water gets to a temperature surpassing 212ºF it starts becoming steam. More About Vent Silencers A vent silencer is a device that is intended to reduce the noise levels created when high-pressure gas or steam is.

Another thing we need to look at when we design vent silencers is the venting conditions. These absorptive silencers are used to suppress noise generated by high velocity gas streams such as steam vents safety relief valve outlets system blow down and purge outlets. This is normally greater than or equal to the permitted silencer back pressure.

Efficient steam silencer design will reduce the noise level in industries that vent steam and other high-temperature fluids. Untreated this flow creates a very objectionable and potentially unsafe noise level. There are several notable sections.

Vent silencers serve a two fold purpose. Each vent silencer is designed to attenuate the noise level to the required sound pressure level criteria at a given distance from. The steam vent silencer model is generated using CATIA V5 R20 pre-processing is carried out using ANSYS WORKBENCH and CFX SOLVER is used for.

For both of them the design is similar since we refer to vent silencers when being used to vent at a constant flow rate for a period of time. Atmospheric vent silencers are designed to cut the noise generated by the expansion of gases from an elevated pressure to atmospheric pressure. We have steam vent silencer designs as well as a number of others.

Some businesses will only vent gas in emergency situations to bring the pressure down in a system. Of reactive and absorptive elements in the vent silencer design. Others only use venting as part of a shutdown for maintenance.

To reduce the intrusion of industrial noise into residential areas. However there are some operators that will have periodic venting to reflect their operations. Dürr Universals vent silencers effectively silence high-velocity air steam and gas vents as well as blowdowns to atmospheres in which sonic or critical flow conditions exist in the valve.

Steam Vent Silencer Design Do-it -yourself Can anyone advise where I can find basic or detaileddesign guide for steam vent silencers. The noise produced is a combination of shock noise generated by the rapid reduction in pressure across the relief device and the noise created by the turbulent flow of gas downstream.

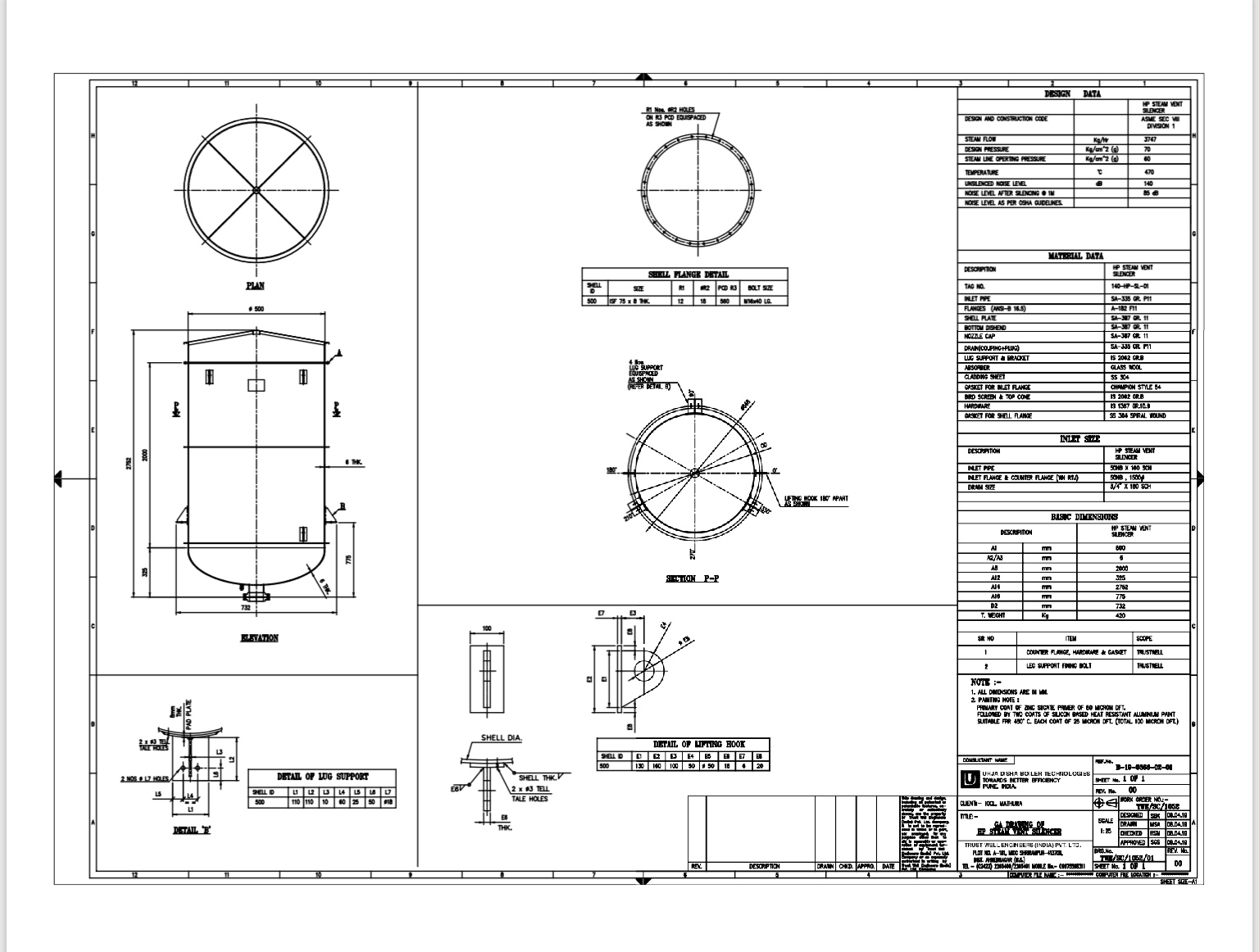

Schematic Of A Pulsco Vent Silencer Download Scientific Diagram

Start Up Vent Silencer P R Acoustical And Engineering Works P Ltd

Cross Section Of The Designed Double Muffler For Steam Vents Noise Download Scientific Diagram

Bachmann Industries India Limited Vent Steam Silencers

Steam Silencers Trust Well Engineers India Pvt Ltd Leading Manufacturer Of Waste Heat Recovery Boilers Steam Coil Air Pre Heater Economizer Soot Blowers Steam Silencers Heat Pipe Recovery System In Pune

Blow Off Silencer And Vent Silencer For Industial Plants

Vent Silencers Controlling Noise Creating Within A Pipeline From Gas Or Steamflow

0 comments

Post a Comment